This is a continuation of a series of posts that I started what seems like a long time ago about getting a book designed and published. The series starts here.

A couple of weeks ago, I participated in a conference call with Jerry Takigawa, and representatives from both Hemlock (the printer) and Roswell (the bindery). The main topic of the call was how to get the pages to lie flatter than they did in the dummy, but we discussed some other issues as well.

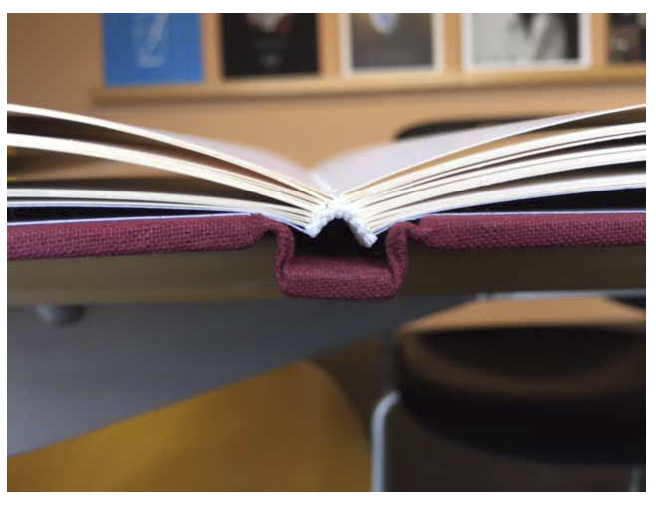

To review the bidding on page flatness, we had received a dummy bound by Roswell where the pages didn’t lie anywhere near flat enough for the photographs that spanned the gutter to work like Jerry and I wanted them to. It turns out that the signatures are glued after sewing with hot melt glue for the dummies, and a glue called PUR for the real books. PUR is more flexible than the hot melt glue. The folks from Hemlock had dealt with a similar issue in the past, and thought that matters could be improved by making the signatures smaller. We agreed to get another dummy made with 14 each 8-page signatures rather than 7 each 16-page signatures that we had been using. We further agreed that the new dummy would be glued with PUR.

After much discussion, we decided that using a vellum flysheet was too risky. The flysheets has wrinkled in one of the dummies, and, although Hemlock thought the odds could be made better, that there’d always be a chance for wrinkles in some of the real books. Jerry has a Plan B: make the first 8 pages, which is now the first signature, from Crest uncoated paper, rework the layout to get the little illustrative photographs out of there.

Following Hemlock’s suggestion, we made the end papers 80# cover stock.

Towards the end of last week, Jerry got the new dummy. I haven’t seen it yet, but Jerry says the pages don’t’ lie any flatter than before. He’s trying to figure out what happened.

Leave a Reply