More than a year ago, I wrote a post on lens adapter tolerance, bemoaning the fact that all the adapters that I’d tested were too short. I followed that up with a post about how, at least in the case of Novoflex, this was on purpose. As I continued to purchase adapters from various manufacturers, all were about 0.5mm too short, which made the readings on the focus scale invalid, threw off parfocality in zoom lenses, and rendered less effective lenses with internal focusing and/or floating elements.

The week before last, I received an adapter from Kipon which allowed me to use my 5 cm f/2 Nikkor-H lens, which was originally designed for Nikon S-mount cameras, on my Sony alpha 7 cameras. For that lens and some others, the helicoid was in the camera body, and thus any adapter has to have such a helicoid so that the lens can be focused. I noticed that the distance scale on the Kipon adapter was accurate. That meant that the adapter wasn’t too short.

I wondered if the tolerances were so tight on this adapter because it had the focusing mechanism built in. In order to gain some insight into the matter, I ordered a Kipon adapter that was set up for mounting a Leica M-mount lens on a Sony NEX, E, or FE mount body. It came yesterday. Today I put it on a Sony a7II, and attached a Leica 50mm Summicron-M ASPH. The focusing scale was accurate. Infinity focus occurred just barely before the infinity stop on the lens, just as it does when that lens is mounted to a real Leica M9 or M240.

So, based on a sample space of two, it’s possible that there’s at least one manufacturer that doesn’t make their adapters deliberately way too short. Hallelujah! I’ve ordered Kipon Nikon F to NEX and Leica R to NEX adapters and I’ll let you know how tight the tolerances are when they arrive.

The whole thing has gotten me thinking in more quantitative terms about adapter tolerance. I’ll share some of those thoughts with you.

First, let’s consider the tolerance situation when a lens is mounted on the camera for which it was designed, with no adapter in the picture. (Note: for this and the ensuing tolerance discussion, I’m going to assume that tolerances are absolute, that if I say the tolerance is 10mm +/- 0.5mm, that means that the shortest the part will be is 9.5mm and the longest it will be is 10.5mm.)

Let’s say that the camera and lens manufacturer sets the flange focal distance to some nominal quantity that we’ll call ffd. Now the manufacturer assigns a tolerance to the cameras ffd, say +/- c and to the lens, say +/- l. Then the camera and lens manufacturer has to design the lens so that it focuses far enough beyond the infinity mark on the lens so that the image will be in focus if the actual worst case flange focal distance of lens and camera is ffd + c + l. You will see the greatest effect on the focusing scales of wide angle lenses.

It has been my experience for manual focusing lenses with precisely marked distance scales, with the exception of one Zeiss 35mm f/2 Biogon that I own but hardly ever use, that the distance scales of these lenses is accurate enough to achieve proper focus wide open by measuring subject distance with a tape measure and setting that value with the focusing ring.

In messing with a bunch of lenses and their native bodies, I estimate that c and l add up to less than 0.05 mm, maybe a lot less. I used Leica M cameras and lenses, Nikon F-mount cameras and Zeiss F-mount lenses for my testing. 0.05 mm may sound small, but converted to inches it’s 0.002. Around the metal shops at Hewlett-Packard (the last ones with which I have any personal experience), +/- 0.001 inches (usually called a mil) for parts the size of a lens adapter, wasn’t considered truly precision machining, but the sort of thing you’d give to the new guy. I should note that the sensors on cameras can be, and often are, shimmed into tolerance, so that the machining requirements are lessened.

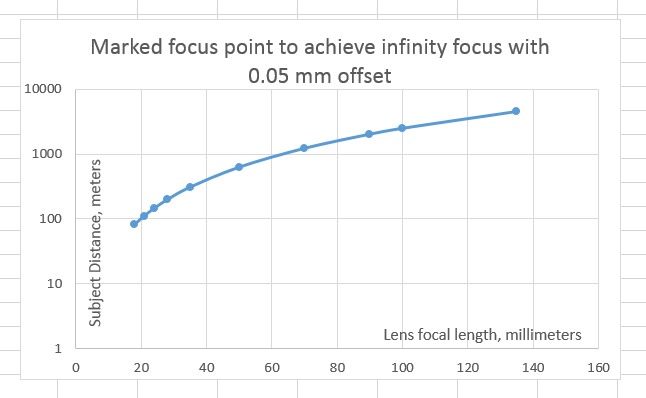

Here’s the worst-case infinity focusing error for the camera and the lens at the end of their tolerance band in the direction that would put the lens closest to the focal plane:

Now, let’s consider adding an adapter into the mix. If we design the adapter’s nominal thickness as the difference in flange focal distances between the camera for which the lens was designed and the camera to which the adapter will let it attach, on average the distance scales on our lens will be just as accurate as they were before the adapter appeared on the scene, but there is the possibility that the adapter will keep a particular camera/lens combination which was out of tolerance in the worst direction from focusing to infinity.

We can keep that from happening by specifying the tolerance for the adapter thickness as +/- a, and making the nominal adapter thickness shorter than the difference in flange focal distances by a. Now, the lens will always focus to infinity if the manufacturers of the camera and lens had similar ideas about what the tolerances should be.

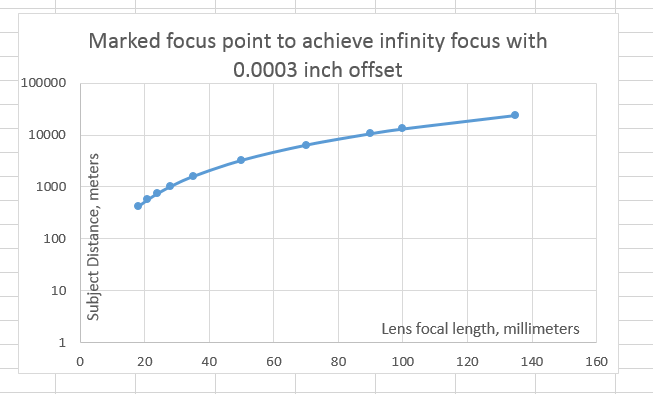

So, what should a be? Let’s assume the adapter thickness is achieved through precision surface grinding. A little Internet research shows that standard surface grinding tolerances are about +/- 0.0003 inches.

Then our nominal adaptor would be too short by 0.0003 inches, and, paired with a nominal camera/lens combination, would produce focusing errors like this:

If the worst-case short adapter were teamed with the worst-case short camera and lens combination, the focusing error would look like this:

Let’s see. An 18mm lens could be off so far that when it’s focused to infinity, the marking on the barrel would say it was focused to about 150 feet, That’s certainly within the tolerance allowed by the depth of field of an 18mm lens, even if it’s fast.

So why do we see adapters from everybody but Kipon — at least everybody I’ve tried: Novoflex, Metabones, Fotodiox, MTF, adn some others — short by so much?

It’s a puzzlement to me. Is it hard for them to hold the kind of tolerances I’m positing above? Are they biasing their design specs so that truly out-of-tolerance lenses, ones that wouldn’t focus to infinity on their native bodies, will focus to infinity on adapted bodies?

I’d appreciate input from anyone who has a good understanding of modern machining tolerances.

Jean Pierre says

You will still have tolarence by manufactoring adatpers! If you will have high precision machine, then the adapter will cost to much, even more then a lens!! And. it is really important to have a right one? No, with focus peaking you can see the focus point. And if you need infinity, then with f 8,0 or higher, the image will be in focus till infinity.

The builtquality is important for me. the concection on both side has to mach with body and lenses, without leaking light in there.

Jim says

Jean Pierre, the point of the measurements that I cited is that the tolerances necessary to make the adapter thickness such that it won’t cause lack of infinity focus and still not materially affect parfocality, the distance scale, and floating element lenses are not difficult by precision machining standards.

Lenses routinely meet those tolerances, and they’re much more complicated devices. In fact, the whole Leica rangefinder system depends on the lenses and camera meeting much tighter standards than I’m proposing.

Jim

CarVac says

While I haven’t held one directly, my understanding is that Leica M lenses only needs two things to be calibrated: the optical assembly offset relative to the flange that contacts the rangefinder lever, and the mechanical ratio linking the lever to the mirror/prism system in the rangefinder.

It shouldn’t particularly care where the bayonet is or whether the lens can focus beyond infinity. That’s why you can adapt screw mount lenses to the bayonet M without an issue.

I think it would care, though, about tilt, although that’s much less of an issue than overall thickness of an adapter.

Jim says

Good point.

Michael says

My skills/knowledge in machining is a few decades old, by I can’t see why a length tolerance in the range of .001″ should be a problem to hold when using either modern CNC machines or older turret lathes, bridgeport mills or even mechanical/hydraulic screw machines. We did that in production using ’60’s and ’70’s vintage NC machines and controllers, and in the 80’s, I taught my students to maintain that precision using both manual and CNC’s, without resorting to grinding. (For surface grinding tolerances, we set a much higher bar).

CarVac says

My adapter (thin one, c/y to eos) has a swappable ring which would presumably be adjusted based on the thickness of the machined part. That would let it meet tight tolerances.

CarVac says

I have a 60d on the “less likely to focus to infinity” side of tolerance.

I once rented a Canon 100-400 mk I; the first copy I received could manual but wouldn’t autofocus to infinity. I also rented a Tokina 11-16; again, the first copy wouldn’t focus to infinity at all, the second only barely would. I’m probably a bit of a thorn in the side of the rental company.

To get to the point: I use a Fotodiox Pro adapter between my Contax lenses and the Canon mount; all of my lenses focus perfectly to infinity, and a little beyond on cold days. Now I’ll have to measure the thickness of it to see if it’s in line with what’s expected.

Robbie says

1) 0.05 mm converts to .0020″, not .0013″

2) Consider length change with temperature variation. An aluminum lens housing will have a CTE of ~22e-6 mm/mm/K. So, for example, in freezing weather (20 K delta T from ambient), with an optical group 100 mm away from the flange, this distance will shrink by .04 mm. For polymer lenses this could be 2 or 3x as much.

Jim says

Robbie,

“1) 0.05 mm converts to .0020″, not .0013″ ”

Thanks for the correction. This makes the point of my post even stronger.

“2) Consider length change with temperature variation. An aluminum lens housing will have a CTE of ~22e-6 mm/mm/K. So, for example, in freezing weather (20 K delta T from ambient), with an optical group 100 mm away from the flange, this distance will shrink by .04 mm. For polymer lenses this could be 2 or 3x as much.”

What you say is true, and needs to be considered by the lens manufacturer to make the lens work on cameras for which it is designed. Assuming that the lens designer has done his work well and provided mechanisms to deal with the situation (having the lens rotate beyond infinity is a common one), an adapter designed as I am suggesting will not make the situation worse, and that’s all that’s needed.

jferguson says

Hi Jim,

I just bought a Sony A7 and have been enjoying trying my old lenses on one of the four adapters I bought. Two were K&F Nikon with the aperture setting rings, one a Fotosy without an aperture setting ring, and one the Fotosy Leica M to A7.

I didn’t measure the Leica adapter but did finds the K&F’s though nicely made are shorter than the fotosy which is pretty close, but also short.

FWIW, in the ’50s when I was more directly involved, most lends mounts were machined a bit short and then shimmed up to specification with very thin brass shims. I had an Exacta I which had three shims, and a Leica IIIA with two. also a Leica IIIC which had just one. They were made for the job and the factory must have had a range of thicknesses.

I’m toying with shimming mine up to specification, assuming that the 28.5MM nikon to sony a7 adapter thickness is correct.

Although it’s true that a properly adjusted Leica rangefinder would allow the face of flange to film plane distance to be off a bit, since it is so easy to have it correct, it’s nuts to think it wouldn’t have been. Additionally, had this dimension ever been off, using a Visoflex (Leica’s single lens reflex adapter) would not have focused accurately.

One last thing which I find pretty amusing. Two of the early interchangeable lens SLR’s were the Exac(k)ta and Pentacon. Initially they had manual apertures. you had to focus and then set the aperture by hand which of course darkened the viewfinder enough to make it difficult to set up the shot.

The first fix for this was what was called a “Pre Set” lens. You set the aperture for what ever you wanted, then focused wide open and just before shooting, you pressed a lever which stopped the lens down to whatever you’d set it for. this is exactly what the aperture rings on our adapters are doing, so if you have lenses which will work with this, and can stand the weight of the adapters this a nice feature.

I am finding that on the A7, I can focus wide-open, then set the aperture to F8 and leave it since the viewfinder is still plenty bright.

And one last thing. I sold my M-summicron many years ago but kept the 2.8 elmar. i always thought the early 3.5 coated elmar I had for the IIIC was a lot sharper than the 2.8. Now that it’s so easy to compare, I find the 55 mm Micro Nikkor, i inherited from my dad much shaper. I could be the sharpness is deceiving – just better contrast on the Nikkor, can’t be sure. Since they weigh about the same, i guess by Elmar will stay retired.

Cheers and thanks for a thoughtful blog.

John

jferguson says

Hi Jim,

I’ve been trying to decide which lenses to take on trip to turkey in June. It looks like it will be a Nikon F4 20, Nikon Micor 3.5 50, and a Nikon E 2.8 100. I have 3 zooms, Nikon 35-105, Vivitar 28-105 and Vivitar 70-210 – all too heavy although the 28-105 isn’t that bad but the nikkor 35-105 is sharper but weighs a ton.

I ended up rejecting the “preset” adapters – too confusing to use because you have to look at them to see whether they are stopped down or not, although you can pick up the symptom with the shutter speed in the finder.

I’ve been setting ISO to as close to 100 as will allow a reasonable shutter speed which for me has to be over 1/125. So I focus wide-open then rack the aperture down until I get least comfortable shutter speed and shoot sometimes 5.6 but usually 8 if I’ve picked ISO well.

So I’m using a couple of Fotosy adapters, one with and one without a tripod mount. combination of primes above and this camera seem a lot more ‘wieldy’ than the zooms. Makes me wonder if Sony would make an A7 without the LCD, just this very nice finder. It’s all i really would want.

Does any of this make sense to you?

John

Jim says

Sure.

Try focusing stopped down; you won’t have to deal with focus shift and you won’t have to fiddle with the aperture control.

Jim

jferguson says

Hi Jim,

thanks for the idea. It’s a good one,

the beauty of the electronic finder is absence of darkness at any reasonable stop. i really wish the controls were a little different, don’t fall readily to hand, and I still have winding lever twitch from all the years with the M2, But I’ll get used to it.

I’m toying with idea of making a custom grip which puts the shutter and focus button where I want them. i have the shop to do this, just have to decide whether I should just relax and live with it, or try to move the focus bit to the roller wheel in front.

j ferguson says

I’m back from the trip. I ended up using the 20mm F4 Nikkor for almost everything – 3800 shots although number without multi shots might be more like 2000. I started out with the color fringe focusing but found it had enough slop to make using the enlarged section system far preferable. I used the Fotosy Nikon/Alpha 7 adapter . It does look as though lens focus on the 20 mm went down very quickly when the setting was past infinity – mount too short.

So I’m getting ready to take the adapter apart, and shim it up to a lot closer. with the F4 lens, grab shots with the thing set to infinity (real infinity) works pretty well if there’s nothing in the foreground.

as an aside, I suspect only another experienced photographer would realize that 90% of my shots were done with a 20mm. Only real problem with this lens is keeping your legs and elbows, sometimes fingers out of the frame.

changing lenses in the field is a real pain. i’d forgotten. i used to shoot with a 35 on an M2 and a 50 on a IIIC with leica’s little Albada finder.

I may wind up with Sony’s 17 to 35 zoom.

j ferguson says

well no joy on shimming the Fotosy. The flange to which the lens is attached sits on a very narrow ledge on the body of the adapter. This is what would need to be shimmed and there just doesn’t seem to be enough meat there. There is a sheet metal spring-plate which keeps the lens tight in the mount.

too bad, I only needed .004 – thickness of sheet of paper.

I guess I need to give up and get one of the better adapters

Jim says

Try Kipon.

j ferguson says

Kipon worked fine for the Nikon lenses – pretty much dead nuts on.

I liked the Nikkor 20mm shots so much, I’m thinking of getting a Leica M mount super angulon and the Kipon M mount adapter to reduce the mass of this thing a bit. Camera alone wasn’t big enough for my hands, so it has a permanent bracket on it but without the vertical side. Friend with Leica M lenses is going to buy one too.

j ferguson says

Using an M-mount Super Angulon with the Sony may not be a very good idea. it has a much closer rear-of-lens to focal plane distance and accordingly rays at the outside of the frame enter the sensor at a greater angle then would rays from an equivalent focal length lens intended for a conventional SLR – has to have enough room to clear the mirror. (this is second hand knowledge form another website which reported the problem from experience but didn’t speculate on the reason. This speculation is mine.